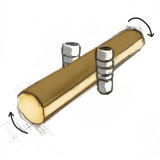

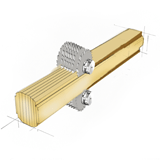

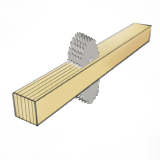

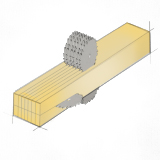

Current profiling technology – Edging of sideboards already on the log

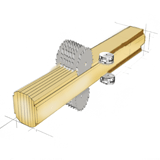

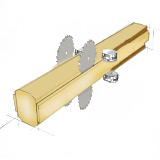

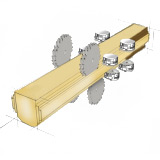

For medium and large capacity requirements up to industrial production, profiling technology has become prevalent. Also in profiling, we start at log lengths of 0.8 m and process log diameters up to 65 cm. SAB has further developed and implemented its profiling lines using flexible and highly productive sideboard edging and cutting technology, and our current profiling units are technologically in no way inferior to traditional edging equipment that requires higher investments and more floor space. All production processes are carried out directly "at the log" without additional auxiliary equipment and without the need for additional floor space in the workshop. This saves building and personnel costs.

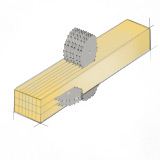

Based on your raw materials situation, we plan and build profiling lines for the production of high-quality timber according to the requirements of your customers. Also the design of our profiling lines starts already with the chipper circulation system. The resulting modular technology can be exactly tailored to your needs. Already during the conception of your customized line, we have potential future changes/extensions in mind.

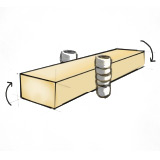

Many of our customers have achieved such economic success with our profiling equipment, that they decided to increase capacities and extend their cutting technology already after short periods of operation. That's why we leave the door open for extending and adapting our lines by applying our consistent modular design from the very outset.